Machine Monitoring Solution

Benefits of Remote Equipment Monitoring Systems

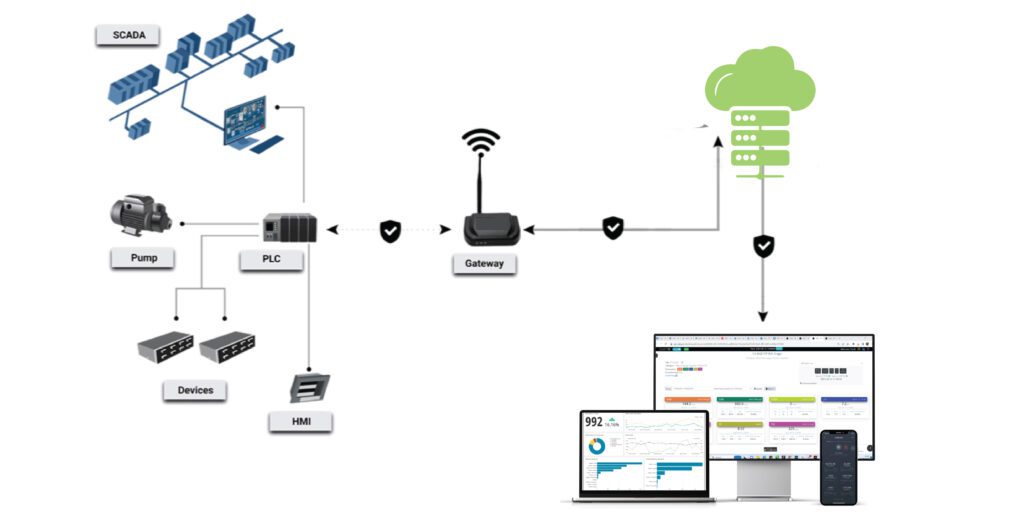

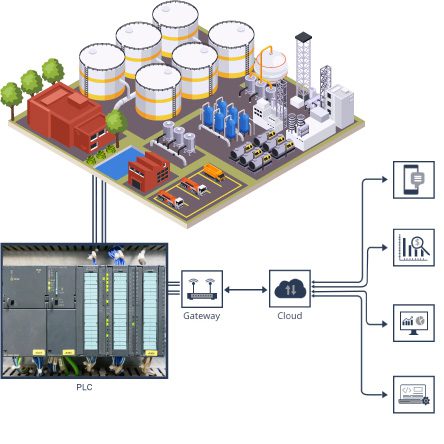

Utilizing the capabilities of the Internet of Things, we at i-telemetry develop cutting-edge remote machine monitoring solutions that come pre-configured and are compatible with legacy machinery, PLCs, and SCADA systems used in various industry sectors. These systems can be tailored to suit any industrial environment, enabling facilities to enhance traditional operations without disrupting production.

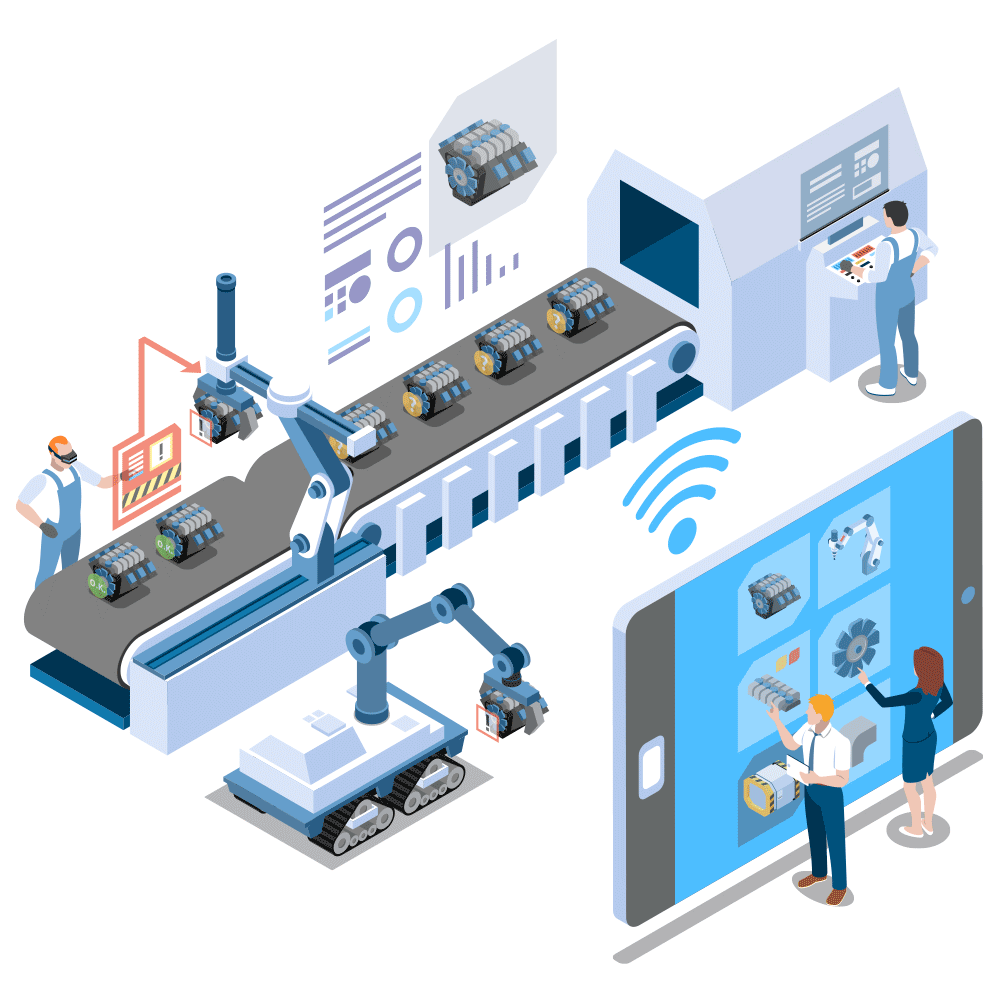

i-telemetry’s Factory and Machine Monitoring Systems empower businesses to pinpoint critical performance indicators, such as uptime and downtime, as well as gain insights into their asset operations and optimization strategies to enhance overall equipment effectiveness.

Problems Associated with Legacy Monitoring Systems

Legacy monitoring systems have persisted in use for many years, often becoming outdated and failing to align with evolving business requirements. This can impede industrial operations significantly. Traditional systems like SCADA and PLC, as well as legacy monitoring systems, gather crucial data about the status and performance of industrial machinery but typically display this information without effectively processing it to meet business demands. In today’s era of globalization, where workplaces are expanding, the rigid, static, and centralized architecture of legacy systems poses a significant challenge in obtaining secure and automatically processed real-time insights from outside the industrial premises.

Enter i-telemetry’s end-to-end IoT-based factory and machine monitoring solutions. These solutions seamlessly integrate with legacy PLC and SCADA systems, enabling industries to efficiently manage their day-to-day industrial operations in real-time, even remotely from their industrial premises.

Common Challenges in a SCADA system

Ineffective for Outside-The-Fence Application

Rigid and Complex due to Wired Infrastructure

Costly and Time-Consuming Integration

Tied only with specific control Devices and Legacy Systems

Inflexible,Static and Centralized Architecture

Less Scalable than other Industrial Control Systems

Not Adaptable to Changing Business Needs

How PLC & SCADA and Industry 3.0 is adopting IoT?

The involvement of IoT and SCADA together is the new upgrade within industries, introducing the next phase of smart manufacturing. The use of IoT makes SCADA systems more intelligent and advanced. IoT complements both distributed control systems and SCADA with its existing features like real-time data collection, downtime alerts, remote control, data analysis, and visualization. The Internet of Things is equipped with advanced capabilities of integrating edge-to-cloud solutions, especially for heavy machines. It helps in fetching accurate and real-time data through connectors and gateways, enhancing the profitability of results. IoT provides a scalable and customizable user-friendly platform to automate the operations along with safety measures, which senses the changing needs of any asset.

- IoT is Integrating Edge-to-cloud solution for heavy equipment/machines

- Connecting nodes/gateway on endpoints of the PLCs

Applications

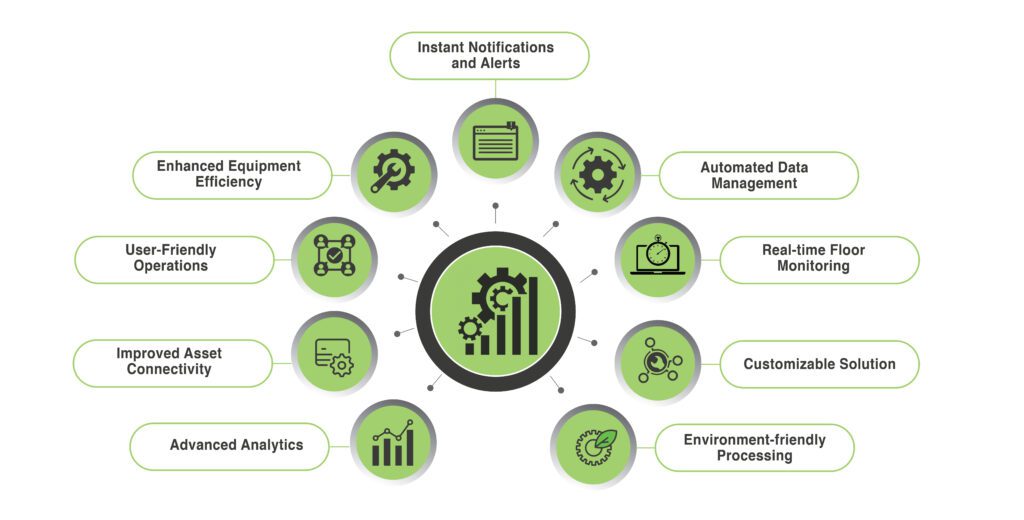

Key benefits of opting i-Telemetry Machine Monitoring Solution

Features of i-Telemetry IoT Based Factory and Machine Monitoring Solution

Architecture Format