Beverage Level Monitoring

In the beverage industry, a diverse range of liquid products, including concentrates, fruit blends, pulp cells, essential oils, purees, and more, are produced. To facilitate their storage and efficient distribution, tanks, drums, tankers, and large containers are employed. With our IoT-based level monitoring system, we enable effective monitoring and management of the products stored in these containers.

The implementation of the i-telemetry level monitoring solution not only enhances warehousing and storage operations in beverage manufacturing companies but also supports automated production and distribution while providing visibility within the supply chain. This aids companies in ensuring just-in-time delivery of their products to customers.

Composition and Working of Beverage Level Monitoring Systems

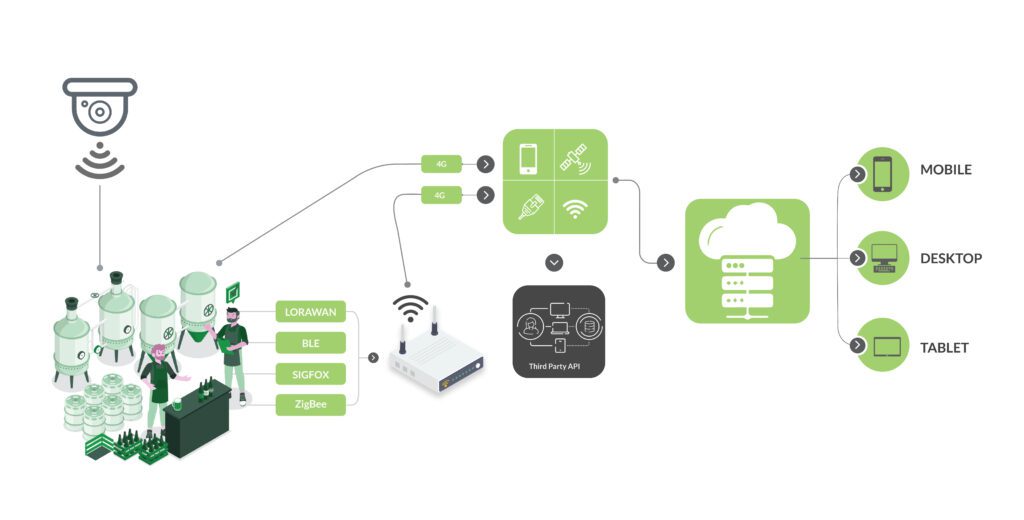

I-telemetry employs contactless sensors to wirelessly gauge the quantity of juice, wine, or any beverage stored in a container. This non-contact level measurement guarantees the preservation of beverage quality by avoiding direct sensor interaction. The information regarding the liquid level is transmitted to a gateway, which subsequently relays it to an application server. Organizations can harness this data through a mobile application or web portal, enabling them to make informed decisions and optimize processes related to beverage storage, distribution, or production.

Beverage Level Monitoring’s Comprehensive Features

The information collected from these tanks can then be analyzed through the dashboard, which includes built-in historical data management and predictive analytics features. This analysis helps in identifying patterns and generating insights that contribute to optimizing decision-making processes, whether to increase production rates or to better manage the tank contents.

Once I-Telemetry sensors are in place, they excel at accurately gauging the juice levels within these tanks, even when they reach towering heights of up to 45 feet. This makes our sensors an ideal choice for implementing monitoring solutions in such large tank configurations.