Corrosive & Toxic Liquid Level Monitoring

I-Telemetry offers a comprehensive solution for monitoring corrosive liquids commonly found in industrial settings. These liquids, such as acids and other caustic substances, have unique properties that make them corrosive to various metals. To address this challenge, our technology is designed to be compatible with these aggressive fluids.

Our state-of-the-art level monitoring solution utilizes a combination of ultrasonic and RADAR sensors. These sensors are not only highly reliable but also capable of withstanding the corrosive fumes emitted by these liquids. Whether you need to monitor the levels of corrosive liquids in stationary storage containers or in moving tanks during transportation, I-Telemetry has you covered. Our advanced sensors ensure accurate and dependable tracking of the liquid’s quantity, providing valuable data for your industrial processes.

How does Level Monitoring System work for Corrosive Liquids?

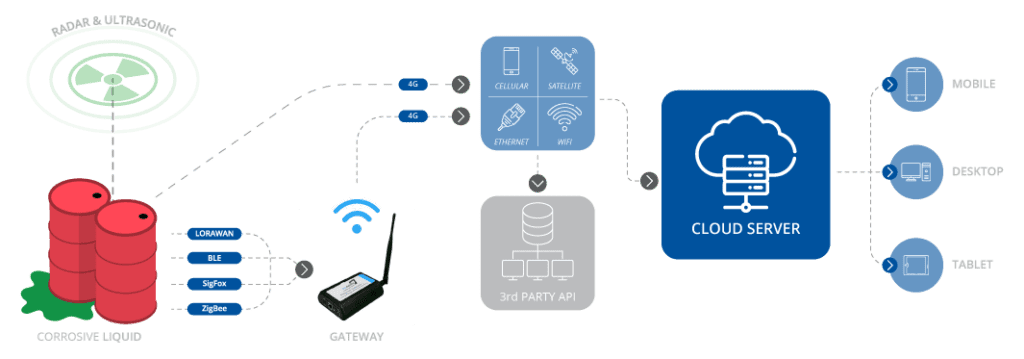

I-telemetry has implemented wireless sensors on the tank containing corrosive liquid. These sensors utilize various technologies such as RADAR and Ultrasonic to emit high-frequency sound pulses and measure the time it takes for the echo to bounce back from the surface of the liquid. This non-contact and automated measurement method ensure that the sensors remain safeguarded from potential damage caused by the corrosive nature of the liquids.

What Features Supports Level Measurement for Corrosive Liquids?

Our comprehensive i-telemetry solution for end-to-end level monitoring, combined with other integrated solutions, can help optimize operations and drive operational excellence. By integrating the i-telemetry liquid level measurement system with various solutions and systems, you can enhance production rates, improve industrial efficiency, and enable automated operations.