Large Storage Level Monitoring Tanks

i-telemetry presents a tailored, branded level monitoring solution designed to accurately measure liquid levels within large storage tanks, capable of reaching heights of up to 6 floors. With our solution, you can easily ascertain the quantity of liquid remaining in stock or projected future requirements, enhancing your industrial plant’s efficiency and return on investment.

Our IoT-powered solution is equipped with advanced analytics, enabling you to make data-driven decisions that lead to improved profitability. Additionally, it offers the convenience of interconnecting multiple storage tanks across your industrial facility through a single dashboard, streamlining your operations and facilitating better oversight. Whether your industry is in oil & gas, beverage, pharmaceuticals, or any other sector utilizing large storage tanks, i-telemetry’s level monitoring solution is here to help you optimize performance and boost productivity.

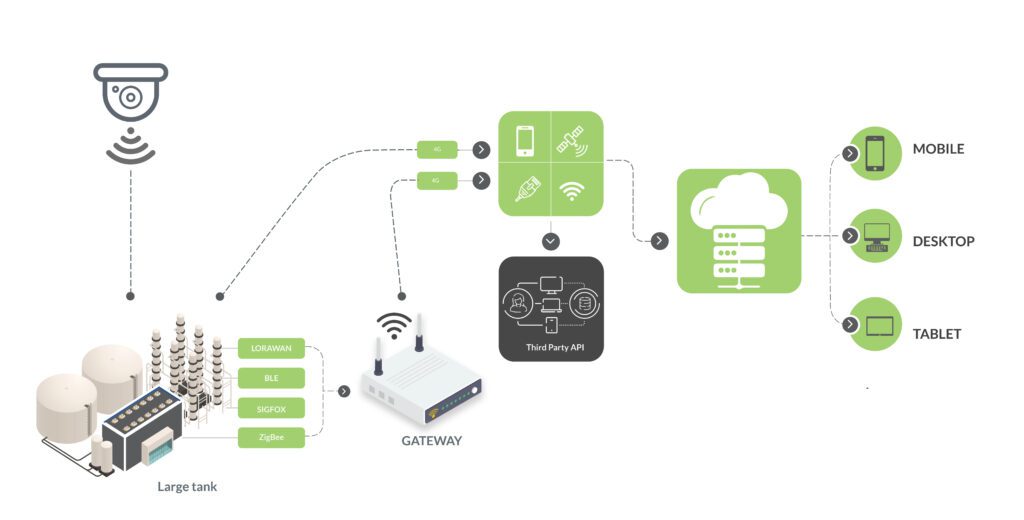

Flowchart explaining the functionality of this solution

Technical Features